| Home |

| About |

| Safety Signs |

| Water-Jet |

| Digital Print |

| Engraving |

| Metal Etching |

| Fixings |

| Materials |

| Contact Us |

| Site Map |

Water-Jet cutting

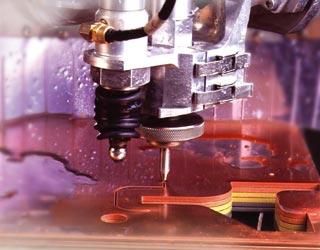

Utilising an jet of intensely pressurised water focussed to an extremely fine point through a precision machined diamond, water-jet cutting is arguably one of the fastest growing machining techniques available to the modern engineer.

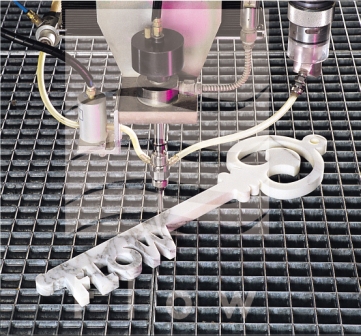

Softer materials such as rubbers and plastics utilise water only, but for harder materials a granular abrasive is metered into the stream and this allows practical cutting of the hardest metals and minerals; granite, titanium, stainless steels are easily dealt with.

Clarity utilises a machine with a bed-size of approximately 1sqm and a carriage height of roughly 150mm allowing an enormous range of materials to be handled.

The cutting head is controlled by a state-of-the-art CNC controller allowing for high precision work combined with a high work rate.

Water-jet cutting offers a number of benefits over other alternative cutting techniques:-

-

Cuts virtually any material

-

No heat generated - a cold cutting process

-

Leaves a quality finish with little or no post-finishing required

-

Can machine composite materials in one pass